Industrial automation and robotics

automation

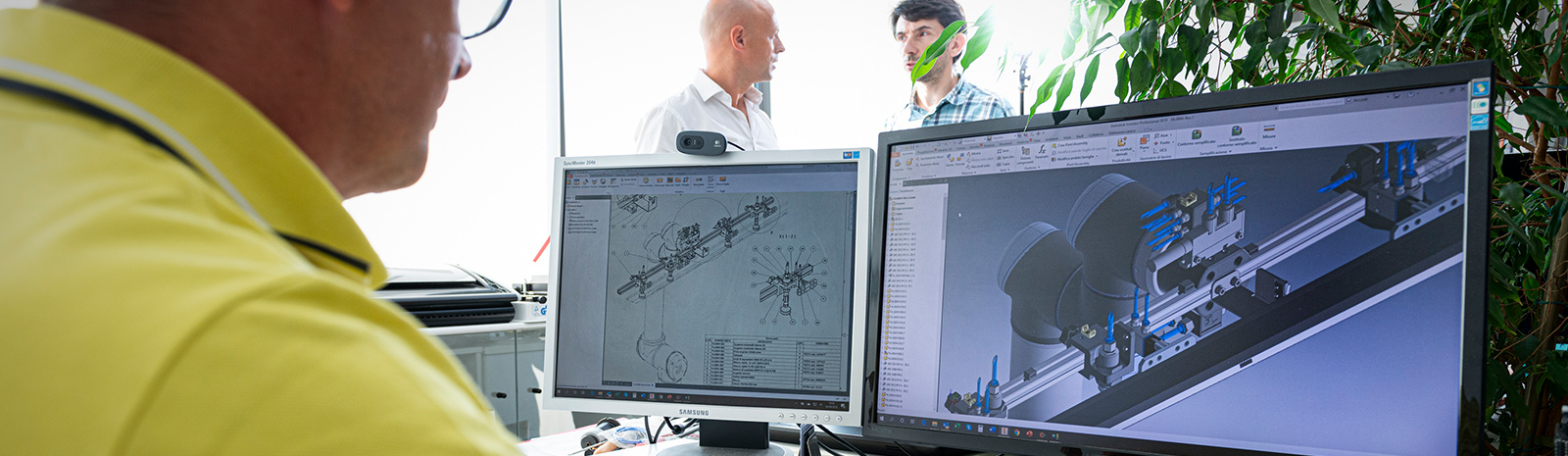

FAST Assembler creates completely customized applications, designed and implemented according to the customer’s needs. The application sectors range from the manufacturing industry to specific sectors, such as paper converting and the textile sector. All applications are designed according to current standards and all related documents are prepared and made available to the customer as required by ISO 9001, for which FAST Assembler is certified.

Industrial

automation

FAST Assembler creates completely customized applications, designed and implemented according to the customer’s needs. The application sectors range from the manufacturing industry to specific sectors, such as paper converting and the textile sector. All applications are designed according to current standards and all related documents are prepared and made available to the customer as required by ISO 9001, for which FAST Assembler is certified.

FAST Assembler

makes use of robot:

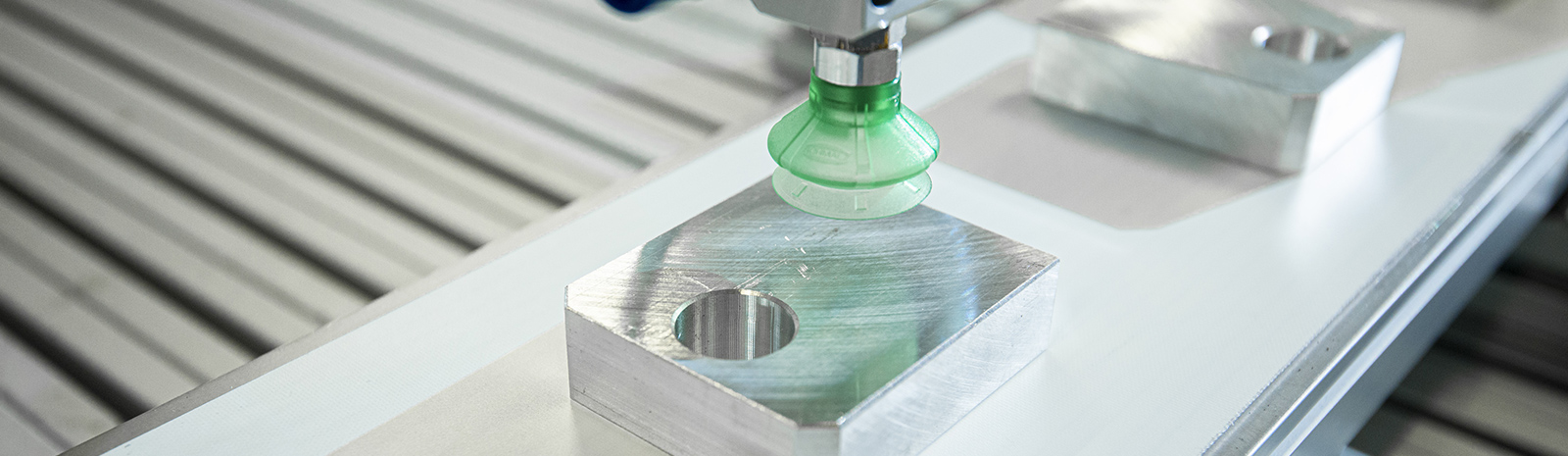

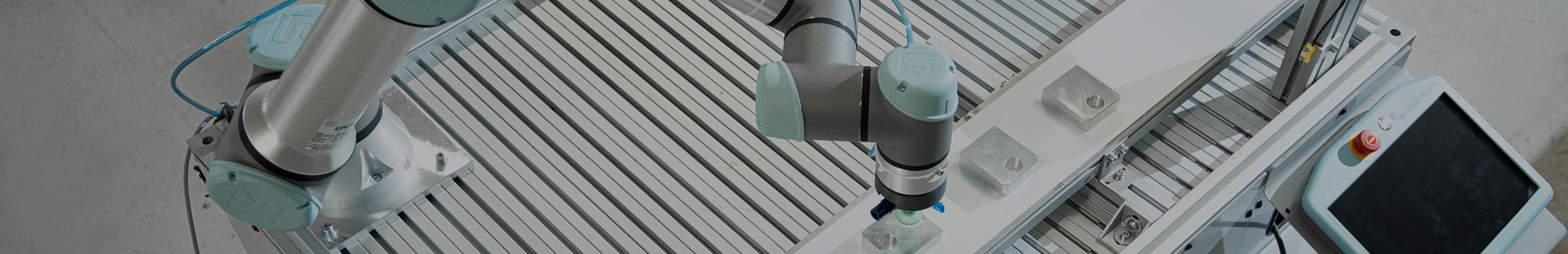

Collaborative

Integration for applications that require man-machine collaboration, for example bringing the artisan assembly to a technologically advanced level. This technology is used in areas where integration must be flexible and predisposed to undergo sudden and drastic changes over time, thus having the possibility of rapid re-deployment. The application sectors range from assembly lines, packaging, food&beverage, to the creation of islands for testing/testing products or machinery.

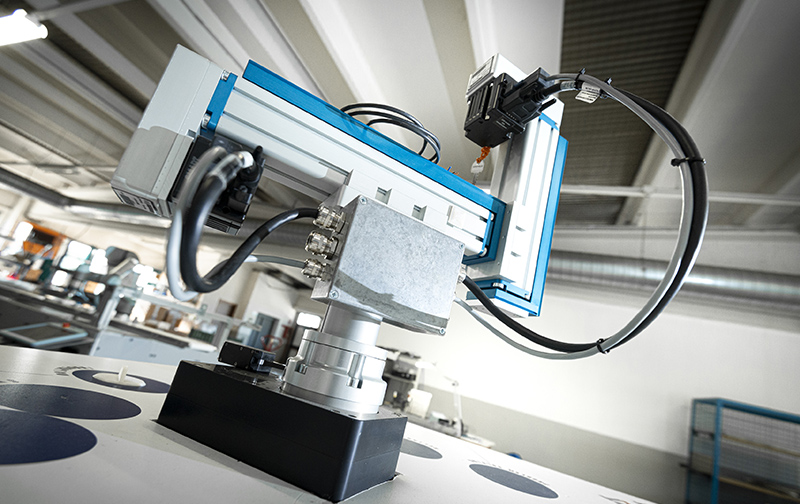

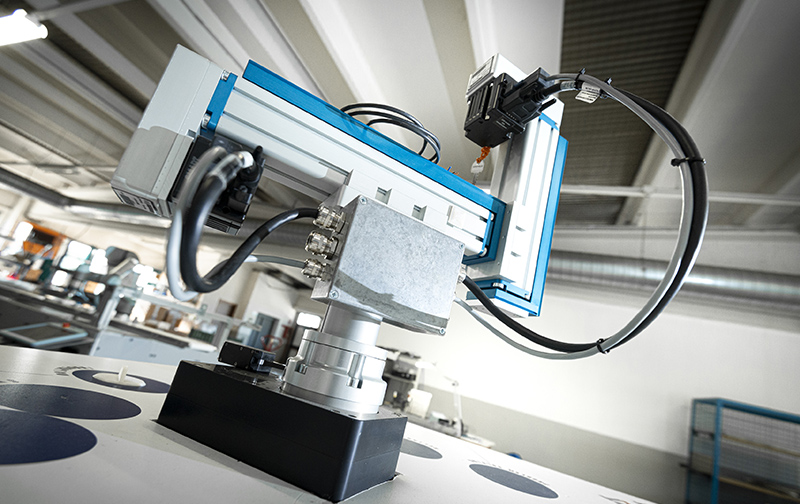

Delta Robots

Where maximum execution speed is required (pick&place, enslavement, sorting, etc.), FAST Assembler is able to create automatic lines, made up of a single or a fleet of Delta Robots, also creating handling tools on specific needs applied to the robot wrist. FAST Assembler integrates this technology mechanically and at the software level in any process or industrial line.

Custom

In the event that commercial technologies do not meet the increasingly close needs of customers, FAST Assembler boasts a fleet of suppliers able to allow it to compose automatisms designed ad hoc.

For any need, please do not hesitate to contact us!

The huge world

of robotics

FAST Assembler has invested in emerging (or rediscovered) robotic technologies, making itself independent in creating applications that make use of robots.

The added value of these technologies is the competence and mastery in the development of dedicated software, allowing you to make the most of the integration potential of these robots or automatic systems.

The huge world

of robotics

FAST Assembler has invested in emerging (or rediscovered) robotic technologies, making itself independent in creating applications that make use of robots.

The added value of these technologies is the competence and mastery in the development of dedicated software, allowing you to make the most of the integration potential of these robots or automatic systems.

Towards

Industry 4.0

Through the implementation of industrial automation and robotics, we quickly get to the new concept of Industry 4.0. Industrial automation through robotic control tends to evolve faster and faster, the purpose of which is represented by automatically advanced processing management.

The increasingly frantic technological development has allowed FAST Assembler to reach and assert itself in the field of industrial automation and robotics quickly, drawing an important benefit from these technologies at the production and assembly line level, in terms of quality and quantity.

The artificial intelligence has allowed the company to obtain excellent results in the products made, where the waste is reduced to a minimum and the precision in each processing phase is almost perfect. Quality is guaranteed to the customer.

The company is investing in a Demo Room, to make these technologies available for tests that simulate the final application of the customer, allowing him to evaluate all the benefits and critical issues before the actual implementation.